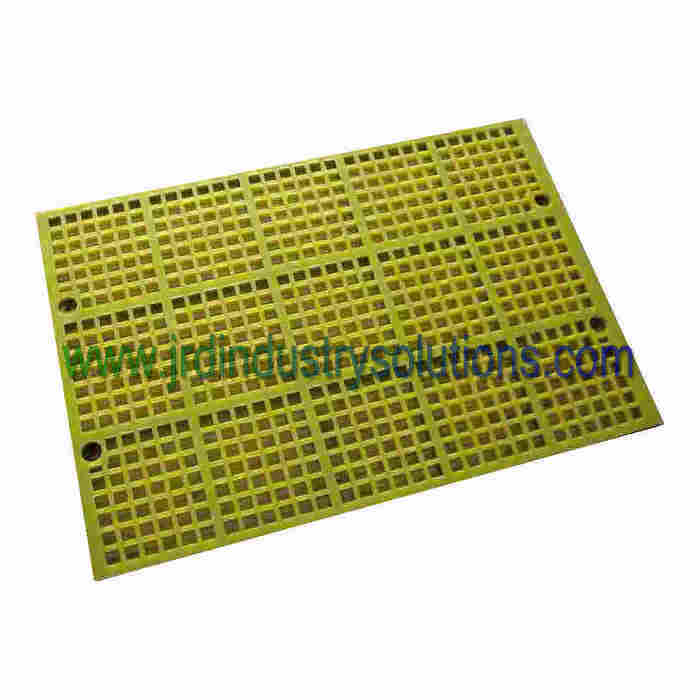

Polyurethane sieve plate is a kind of raw material for producing mesh products with polyurethane as raw material.

Screen Pass: Sewing, Rectangular, Circular, Square

Main application industries: coal washers, coking plants, mines, power plants, dredging companies, metallurgical, petroleum, petrochemical and other enterprises.

Main Applied Equipment: Vibrating Screen

Main performance characteristics:

1. It has good wear resistance and long service life. Its wear resistance is 3-5 times that of steel sieve plate and 5 times that of ordinary rubber sieve plate.

2. Maintenance workload is small, polyurethane sieve plate is not easy to damage, and its service life is long, which can greatly reduce the maintenance amount and the loss of shutdown maintenance.

3. Low cost. Although the investment of polyurethane sieve plate with the same specification (size) is higher than that of stainless steel sieve plate (about 2 times), the total cost of polyurethane sieve plate is low because its life expectancy is 3-5 times of the size of stainless steel sieve plate and less maintenance and replacement. Not high, the economy is also very economic.

4. It has good moistureproof performance and can work in the condition of water as medium. In the case of water and oil, the friction coefficient between polyurethane and material decreases, which is more conducive to the screen, improves the screening efficiency, and avoids the adhesion of wet particles. At the same time, it reduces wear and prolongs service life because of the low friction coefficient and cold.

5. Corrosion resistance, non-flammable, non-toxic and tasteless.